- Piston travel in cylinder varies by as much as 6 mm or about 1/4 inch

- Multilink system and electric actuator reduce or increase piston stroke

- Compression ratio varies from 8.1 to 14.1 based on vehicle speed and load

- Engine also includes dual fuel injection systems, turbocharger and variable valve timing

- Fuel economy gain over outgoing V-6 is expected to be about 27%

- System components add about 22 lbs. in weight and about 10% in cost over traditional turbo-4 engine

- First application: 2019 Infiniti QX50 due in 2018

PHOENIX — Drivers of vehicles with turbocharged engines know they can have either pleasing performance or great fuel economy — but not both at the same time.

Nissan says its new variable compression turbocharged engine — called the VC-Turbo — finally will solve that problem when it arrives next year in the redesigned 2019 Infiniti QX50 crossover.

The 2.0-liter four-cylinder engine is rated at 268 hp and 288 pound-feet of torque. And Nissan says the VC-Turbo, which requires premium fuel, delivers the efficiency of a diesel without the cost and complexity. The 2019 QX50's city-highway combined fuel economy is expected to be 27 percent greater than on the outgoing V-6-powered QX50, Nissan powertrain chief Shinichi Kiga told Automotive News at a technical presentation here this month.

For now, the QX50 will be the only vehicle to get the innovative engine. But it could spread to other vehicles at Nissan Motor Co. and Renault.

Engineers have long known that engine efficiency can be greatly improved by varying the compression ratio based on the engine's speed and load. In fact, engine designers have been tinkering with ways to vary compression since the 1920s.

But nothing ever made production. Most recently, Saab experimented with the technology nearly two decades ago using a movable cylinder head.

Nissan began developing its technology 20 years ago, Kiga said.

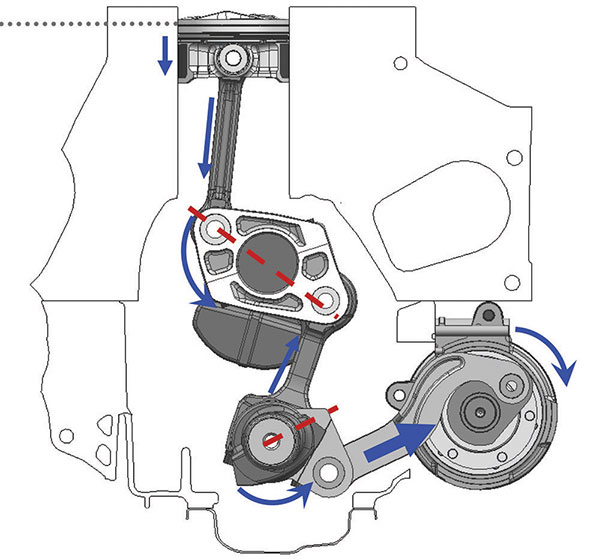

The VC-Turbo rewrites the book on engine design. It decouples the connecting rods from the crankshaft and adds several new components in one of the most significant internal changes to the automobile piston engine in recent decades.

In all other automotive piston engines, the crankshaft moves the pistons up and down in their cylinders, with a fixed distance on every stroke.

Source: AN

The compression ratio is determined by the space above the piston when it is all the way up in the cylinder. The higher the compression ratio, the more efficient the engine — and the more power it makes.

But Infiniti's VC-Turbo uses a pivoting multilink system attached to the crankshaft where the connecting rods usually go.

When an electric actuator pushes up on the side of the multilink, opposite the piston, it tilts the piston side down. That prevents the piston from reaching the top of the cylinder. That is low compression mode.

When the actuator pulls down on the multilink, the piston side rises. That causes the piston to travel to the top of the cylinder, which raises compression.

The distance the piston travels in the cylinder varies by as much as 6 mm, or a quarter of an inch, Kiga says, giving the engine a compression ratio that continuously varies from 8.1 to 14.1, depending on the speed and load of the engine.

Commercialization